7 CAD Mistakes That Derail AV Projects

In today's competitive AV industry, it's more important than ever to get designs right the first time to deliver projects on-schedule and on-budget. AV CAD software like AutoCAD, Revit, and dedicated AV system integration software can be extremely powerful for streamlining designs - but only if used correctly. Avoiding common CAD pitfalls is critical for AV system integrators looking to impress clients and grow their business.

In this in-depth blog post, I'll share my insights on 7 of the most common and damaging CAD mistakes that can derail AV projects. I'll discuss the importance of avoiding these mistakes and provide actionable tips and best practices you can implement in your own design workflows. I'll also share some real-world case studies that highlight the negative impacts CAD mistakes can have on AV projects and client relationships.

Whether you're a veteran AV designer or just getting started with CAD, this post will equip you with the knowledge you need to sidestep project-killing mistakes. By the end, you'll have a solid understanding of the most frequent CAD issues that plague AV projects and how to avoid them using industry-leading tools and techniques.

So let's dive in and explore the 7 CAD mistakes you can't afford to make on your next AV project!

Mistake #1: Inaccurate or Incomplete As-Built Drawings

One of the most fundamental and disastrous CAD mistakes is starting a design based on inaccurate or incomplete as-built drawings of the existing space and systems. As-builts are critical for depicting the current state of the facility so that new AV systems can be integrated properly. However, many projects kick off with as-builts that are outdated, lacking in detail, or just plain wrong.

Trying to design a complex AV solution without reliable documentation of the facility conditions is like trying to navigate a new city without a map. You're likely to get lost, frustrated, and waste a lot of time and effort. Even worse, incorrect as-builts often lead to systems that don't fit or integrate properly with the physical space and existing infrastructure.

Some common issues stemming from bad as-builts include:

- Improper placement of equipment, speakers, displays, etc. due to inaccurate room dimensions and architectural elements in the CAD drawings

- Ordering the wrong quantities of cables, hardware, and other components because the as-builts didn't reflect the true scope

- Difficulties integrating with mechanical, electrical, and plumbing systems that were depicted incorrectly or omitted from the drawings

- Scheduling delays and change orders due to unforeseen conditions that pop up during installation

The solution is to invest time upfront to verify and update the as-built drawings before diving into system design. Don't assume the CAD files provided by the client or contractor are accurate - do your own site surveys and field measurements to confirm.

Use a combination of manual documentation and cutting-edge technology like 3D scanning and drone photography to efficiently capture the site conditions.

It's also critical to establish a clear process for controlling and communicating any changes made to the as-builts throughout the project lifecycle. Use cloud collaboration features of your AV CAD software to share updates in real-time with all stakeholders. By starting with a solid, reliable foundation in your as-built drawings, you'll avoid a host of downstream mistakes and headaches.

Mistake #2: Rushing the Design Phase

Another common misstep is feeling pressure to rush through the design phase in order to meet tight deadlines or respond to client demands for immediate solutions. While the desire to be responsive and fast-paced is understandable, trying to shortcut the design process inevitably leads to subpar results and mistakes.

Designing an effective AV system requires methodical planning, careful consideration of project requirements, and attention to detail. Rushing to push out designs quickly often causes important elements to be overlooked or half-baked. Some frequent problems that crop up include:

- Inadequately defining project scope, leading to improperly sized systems

- Neglecting to gather detailed user requirements and preferences

- Choosing the wrong equipment for the application and environment

- Over- or under-engineering system functionality and performance

- Lack of coordination with related trades and disciplines

- Errors and omissions in the CAD drawings and documentation

While it may seem counterintuitive, investing more time in the initial design phase will actually save time and money over the full project lifecycle. Proper planning prevents poor performance, as they say. By being disciplined in your design approach and resisting unrealistic demands to turn around designs at breakneck speeds, you'll produce much better outcomes.

Some tips for managing the design phase effectively include:

- Insist on having a detailed scope of work and design requirements document before starting CAD drawings

- Gather input from all relevant stakeholders, including end users, early in the design process

- Develop a design checklist to make sure no important items are missed

- Allocate sufficient time for internal design reviews and quality control checks

- Leverage manufacturer design assistance and AV system integration software to streamline product selection and system configuration

- Communicate clearly with clients about your design process, timelines, and milestones

Mistake #3: Lack of Design Standardization

Standardization is a concept that doesn't always get the attention it deserves in AV design. But failing to develop and follow consistent standards is a recipe for mistakes and inefficiencies, especially when working on multiple projects with larger teams.Without clear standards, your CAD drawings will be inconsistent and more difficult to interpret.

Design quality will vary based on the individual working on the project. Seemingly basic things like drawing layer structures, text sizes, equipment symbols, and notation formats will be all over the map. This lack of standardization causes confusion, errors, and wasted effort.

The solution is to invest time in developing a CAD standardization guide for your company. This should be a living document that outlines all of the standards and best practices to be followed for AV system designs. Some key items to address in your standards include:

- Drawing templates with consistent title blocks, logos, and layouts

- Layer naming conventions and color standards

- Equipment symbol libraries and nomenclature

- Wire labeling and cable management strategies

- Annotation formats and styles

- Deliverable requirements for different project phases

By getting everyone on the same page and working with a standardized approach, you'll see a noticeable uptick in design efficiency and quality. CAD standards ensure that drawings are uniform and professional-looking. They make it easier for team members to jump in and assist on projects because they can quickly understand the drawing structure and conventions.

Many AV CAD software platforms have built-in tools for developing and managing CAD standards. Features like drawing templates, symbol libraries, and annotation styles can be customized and shared across the team. Look for software that enables you to embed your standards directly into the program to automate enforcement.

Standardization does require an upfront investment and ongoing management. But the return on investment is substantial in terms of reduced mistakes, streamlined workflows, and enhanced collaboration. Make CAD standards a priority and you'll reap the benefits in all of your AV designs.

Mistake #4: Ignoring Equipment Dimensions and Clearances

AV systems are ultimately physical products that have to be installed in real-world environments. However, I've seen countless cases where designers get so focused on the system functionality and signal flow that they neglect the spatial constraints and logistical realities.

A shockingly common mistake is failing to account for the actual dimensions of AV equipment and the required clearances for proper installation and serviceability. Designers often layout racks, cabinets, and credenzas in their CAD drawings without verifying that the gear will actually fit. They neglect to leave adequate space for cable management, ventilation, and access to ports and controls.

The consequences of this mistake can be severe, including:

- Ordering equipment that is too large for the allotted space, leading to costly exchanges and delays

- Frustrated installation techs having to play Tetris to make everything fit on-site

- Maintenance nightmares due to densely packed, hard-to-service racks

- Overheating and reduced lifespan of equipment due to lack of airflow

- Angry clients who expected a clean, well-organized system but got a rat's nest instead

The good news is that these problems are easily avoidable with some basic due diligence during the design phase. Always take the time to look up the dimensions and clearance requirements for every piece of equipment going into your system. Most manufacturers provide CAD blocks or 3D models of their products which can be imported directly into your drawings for accurate layouts.

In addition to checking the equipment fits, be sure to incorporate plenty of extra space for cable management and serviceability. Provide clear diagrams showing the optimal rack layouts and elevations. Consider things like power and thermal management, particularly for large systems with multiple racks.

If you're working on projects with complex architectural conditions or constraints, consider using advanced tools like 3D CAD modeling and VR visualization. These allow you to virtually build out the system and identify spatial conflicts before finalizing your design.

By paying close attention to the physical aspects of the system and accounting for real-world installation conditions, you'll avoid a multitude of mistakes and headaches. Your install team will thank you and your clients will be much happier with the end result.

Mistake #5: Poor Cable Management and Signal Flow

Proper cable management and signal flow are essential for system performance, reliability, and serviceability. However, these aspects are often given short shrift in AV system designs. I've seen far too many projects where the cabling was an afterthought and the signal flow was convoluted and confusing.

Common mistakes in this area include:

- Underestimating the quantity and size of cables required, leading to congested pathways and stressed connections

- Neglecting to plan out logical and efficient cable routes, resulting in haphazard, hard-to-trace runs

- Failing to provide adequate labeling and documentation of cables and termination points

- Creating overly complex or illogical signal flows with too many converters and potential points of failure

- Improper cable selection for the signal type, distance, and environment

The impacts of poor cable management and signal flow can be significant. Physically, it leads to rats' nests of tangled wires that are difficult to install and service. Cramped cables can put stress on terminations, leading to signal dropouts and failures over time. Lack of labeling and documentation makes troubleshooting a nightmare when issues arise.

From a performance standpoint, poor signal flow can degrade audio and video quality, introduce latency, and create incompatibilities between devices. Over-complicated signal chains are inherently less reliable and more prone to failure. And of course, the time and frustration of dealing with these issues equates to reduced profitability for integrators.

The key to avoiding these problems is to treat cable management and signal flow as critical design elements, not afterthoughts. Develop a logical and well-documented cabling plan early in the design phase. Clearly define the signal flow and look for ways to simplify and streamline it.

Use your AV CAD software to create detailed cable schedules, labeling schemes, and wiring diagrams. Show cable pathways on your plan views and consider including cable tray or conduit details as needed. Leverage features like cable ID and signal flow tools to automate documentation.

When selecting cabling, always refer to the manufacturer's recommendations and industry standards. Don't try to skimp on cable quality or size. Use plenum-rated cables where required and select the appropriate shielding and insulation for the environment. Consider color-coding cables by signal type to make identification easier in the field.

Finally, make sure to coordinate with other trades like electrical and IT to ensure your cabling will play nice with other low-voltage systems. Develop a collaborative approach and communicate clearly to avoid conflicts.

By putting cable management and signal flow at the forefront of your system designs, you'll end up with projects that are easier to install, perform better, and are more serviceable in the long run. Don't make the mistake of leaving these critical elements to chance.

Mistake #6: Inadequate Coordination with Other Trades

AV systems don't exist in a vacuum - they have to integrate with a host of other building systems and infrastructure. However, one of the most persistent mistakes I see in AV designs is a lack of coordination with other trades. Too often, AV is treated as an isolated discipline, leading to conflicts, change orders, and delays during installation.

Some common coordination missteps include:

- Failing to account for the location and capacity of electrical power for AV equipment

- Neglecting to coordinate with HVAC for proper cooling and ventilation of AV rooms and racks

- Not leaving adequate space for AV cabling in shared pathways like cable trays and risers

- Lack of coordination on floor box and wall plate locations

- Incompatible ceiling types or plenum spaces for speaker and projector installations

- Furniture and millwork that doesn't properly accommodate AV equipment

The costs of poor coordination can be substantial in terms of time, money, and frustration. Installers show up on-site to find there's no power where they need it or the projector won't fit in the ceiling pocket provided. Electricians and AV techs end up fighting over limited cable tray space. Suboptimal environmental conditions lead to equipment failures down the road.

The solution is to prioritize early and ongoing coordination with all relevant stakeholders. This starts with a kickoff meeting to review the AV scope and identify potential coordination items. Regular check-ins should be scheduled throughout the design phase to ensure everyone is on the same page.

Using the collaboration features of your AV system integration software platform is also key. Many programs allow you to share your CAD drawings and models with other trades and collect their feedback and markups digitally. This is much more efficient than emailing files back and forth or trying to coordinate via phone and in-person meetings.

In addition, be sure to participate in formal coordination and clash detection processes. This may involve exporting your CAD files for integration into a federated BIM model or running clash detection in Navisworks or a similar program. These exercises will identify conflicts and coordination issues before they become problems in the field

.Finally, don't be afraid to ask questions and seek input from other trades. Foster a collaborative mindset and be proactive about communication. No one expects you to be an expert in every discipline, but by working together and sharing information, you can avoid costly mistakes and deliver a well-coordinated system.

Mistake #7: Insufficient Documentation and Deliverables

The final mistake on our list is one that often gets overlooked in the rush to finish a design - insufficient documentation and deliverables. It's easy to view creating thorough drawings, details, and specifications as a tedious chore. However, skimping on the documentation is a surefire way to cause problems downstream.

Inadequate or unclear documentation leads to a host of issues, such as:

- Errors and omissions that require costly rework and change orders

- Confusion and miscommunication among team members and stakeholders

- Difficulty getting accurate bids and proposals from subcontractors and vendors

- Inconsistencies between the design intent and the actual installation

- A lack of clear as-builts and close-out documentation for the owner

The consequences of poor documentation are felt throughout the project lifecycle. During construction, installers are left guessing at the designer's intent, leading to mistakes and delays. Inaccurate or incomplete bid documents result in costly change orders and budget overruns. And once the system is turned over, inadequate as-builts and O&M manuals make it difficult for the owner to properly use and maintain the system.

To avoid these problems, make documentation a priority from day one. Use industry-standard drawing templates and specifications to ensure consistency and completeness. Leverage the automation features of your AV CAD software to generate schedules, details, and other deliverables directly from your models.

Be sure to include all relevant information for installation and commissioning, such as:

- Detailed floorplans, RCPs, and elevations

- Rack layouts and elevations

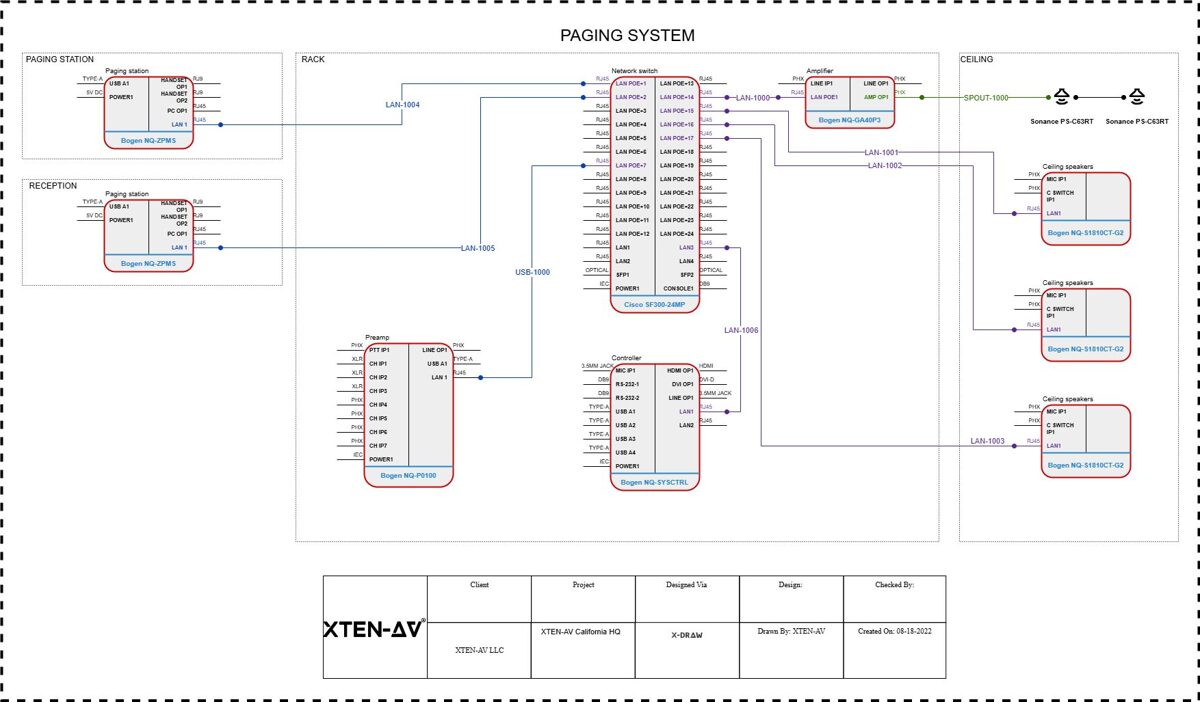

- Schematic diagrams and wiring details

- Cable schedules and termination charts

- Equipment lists and cut sheets

- Control system programming and user interface requirements

- Testing and commissioning procedures

In addition, consider providing 3D renderings or virtual walkthroughs to help stakeholders visualize the finished system. Many clients appreciate these immersive visualizations and they can be a great tool for identifying potential issues before construction begins.

Finally, don't neglect the close-out documentation. Provide a complete set of as-built drawings that accurately reflect the final installation. Develop user-friendly O&M manuals with clear instructions for operating and maintaining the system. And consider offering training sessions to ensure the owner's staff is comfortable with the new technology.

By investing time and effort into creating thorough, accurate, and professional documentation, you'll set your projects up for success. Your team will have the information they need to execute the design efficiently and effectively. And your clients will have a valuable resource for operating and maintaining their AV investment for years to come.

Real-World Case Studies

To illustrate the real-world impacts of AV CAD mistakes, let's look at a couple of case studies from my own experience as an AV system integrator.

Case Study 1: The Perils of Poor Coordination

On a recent higher education project, our AV design team fell victim to mistake #6 - inadequate coordination with other trades. The project involved installing a large video wall and sound system in a new lecture hall.

During the design phase, we failed to properly coordinate with the electrical and HVAC contractors. We didn't provide detailed power requirements for the video wall equipment or specify the necessary cooling capacity for the AV rack room. We also didn't leave enough space in the above-ceiling pathways for our cabling.

As a result, when our installation crew arrived on-site, they found that there were no power outlets or data connections where we needed them for the video wall. The electrical contractor had to scramble to add additional circuits and junction boxes, which delayed our work and added cost to the project.

Even worse, the HVAC system couldn't keep up with the heat load from the equipment in the rack room. The space quickly became overheated, causing several components to fail prematurely. We had to bring in portable AC units as a temporary fix until the HVAC could be upgraded.

In the end, the project was completed successfully, but not without significant stress, delays, and added expense. Had we prioritized coordination early in the design phase, these issues could have been avoided entirely.

Case Study 2: The Cost of Incomplete Documentation

On another project for a corporate client, we made the mistake of providing incomplete and inconsistent documentation. The project scope included AV systems for a dozen conference rooms and a large divisible training room.

In our haste to meet the client's aggressive timeline, we rushed through the design documentation. Our drawings were missing key details like speaker mounting heights, wire routing, and rack elevations. We also had several inconsistencies between the floorplans, schematics, and equipment lists.

When it came time to install the systems, our techs had to constantly reach out to the design team for clarification. In some cases, they had to make judgment calls in the field, which led to deviations from the original design intent.

The lack of clear documentation also made it difficult for the owner's IT staff to properly configure and maintain the systems after turnover. They had to rely on our team for basic troubleshooting and support, which strained the relationship.

While we ultimately delivered functional systems that met the client's needs, the process was far more painful than it needed to be. Taking the time to create thorough, accurate, and consistent documentation would have saved countless headaches and improved the overall client experience.

These case studies underscore the importance of avoiding common AV CAD mistakes. By learning from the missteps of others and implementing best practices in your own designs, you can deliver better projects with fewer problems.

Conclusion: Avoiding Mistakes for AV Project Success

As we've seen, CAD mistakes can have serious consequences for AV projects. From inaccurate as-builts to lack of coordination and incomplete documentation, even small errors in the design phase can snowball into major issues during installation and beyond.

However, by being aware of these common pitfalls and taking proactive steps to avoid them, AV system integrators can set their projects up for success. This includes:

- Verifying and updating as-built drawings before starting design

- Resisting pressure to rush through the design phase

- Developing and following CAD standards across the organization

- Accounting for equipment dimensions and required clearances

- Prioritizing cable management and clear signal flows

- Coordinating early and often with other trades and stakeholders

- Creating thorough, accurate, and professional documentation

Leveraging the right tools and technology is also critical. AV CAD software like AutoCAD, Revit, and D-Tools can streamline the design process and catch potential mistakes before they become problems. Integrated AV system integration software can help with everything from schematic design to rack layouts to generating detailed documentation.

But perhaps most importantly, avoiding mistakes requires a commitment to quality and attention to detail at every stage of the design process. It means taking the time to do things right the first time, even when under pressure to move quickly. And it means being willing to learn from past projects and continuously improve your approach.

By avoiding these 7 common CAD mistakes and embracing industry best practices, AV system integrators can deliver projects that exceed client expectations and drive business success. The key is to stay focused on the details, leverage the right tools and processes, and never stop learning and improving. With the right approach, you can design AV systems that are reliable, user-friendly, and built to last.

Frequently Asked Questions

Before we wrap up, let's address some common questions that come up when discussing CAD mistakes and best practices for AV system design.

Q: How can I get my team to buy into new CAD standards and processes?

A: Implementing new CAD standards and design processes can be challenging, especially with a team that is set in their ways. The key is to involve your team in the development process and clearly communicate the benefits of the changes. Solicit feedback and ideas from your designers and make sure they feel heard. Provide training and support to help them adapt to the new approach. And be sure to celebrate successes and share positive results to reinforce the value of the standards.

Q: What are some of the most important things to look for when evaluating AV CAD software?

A: When comparing AV CAD software options, some key features to look for include:

- Robust symbol libraries and manufacturer-specific content

- Automated tools for generating schedules, drawings, and reports

- Collaborative features for sharing designs and markups with team members and stakeholders

- Compatibility with related programs like Revit, Navisworks, and D-Tools

- Integrated project management and estimation capabilities

- Responsive technical support and training resources

Q: How much detail should I include in my AV system documentation?

A: The level of detail required in your AV system documentation will vary depending on the project size, scope, and complexity. However, as a general rule, it's better to err on the side of providing too much information rather than too little. At a minimum, your documentation should include:

- Detailed floorplans and RCPs showing equipment locations and cable routes

- Rack layouts and elevations with clear labeling and dimensions

- Schematic diagrams showing signal flows and connections

- Equipment lists with full product details and quantities

- Cable schedules and termination charts

- Control system programming and user interface mockups

- Testing and commissioning procedures

Q: What are some best practices for coordinating with other trades on an AV project?

A: Effective coordination with other trades is essential for avoiding conflicts and ensuring a smooth installation. Some tips for improving coordination include:

- Identify all relevant stakeholders and trades early in the project and establish clear lines of communication

- Schedule regular coordination meetings to review progress, identify potential issues, and align on next steps

- Use collaborative tools like BIM and cloud-based file sharing to facilitate real-time coordination and markup

- Provide clear and detailed information about AV system requirements, including power, cooling, and space needs

- Participate in formal clash detection and coordination processes to identify and resolve conflicts before construction begins

- Foster a culture of collaboration and proactive problem-solving among all team members

Closing Thoughts

We covered a lot of ground in this post, from the 7 most common and costly CAD mistakes to real-world case studies and best practices for avoiding them. While it's impossible to eliminate all errors and issues from the AV design process, by being aware of these pitfalls and taking proactive steps to mitigate them, you can significantly improve your odds of success.

At the end of the day, delivering great AV projects requires a combination of technical skill, attention to detail, and effective communication and collaboration. It means investing in the right tools and processes, and continually refining your approach based on lessons learned.

Whether you're a seasoned AV design professional or just starting out in the field, I hope this post has given you some valuable insights and actionable tips for avoiding costly mistakes and delivering better projects. By embracing these best practices and staying focused on quality and client satisfaction, you can build a thriving AV integration business that stands the test of time.

Thank you for reading, and happy designing!